ACP Sheets and the Need to Understand Grades

Aluminium Composite Panels (ACP sheets) have become an indispensable material in modern architecture and infrastructure development. Their lightweight structure, high durability, versatile applications, and aesthetic diversity make them the go-to material for facades, interiors, signage, and more. As architects and builders strive to meet both performance and design standards, understanding the technical intricacies of ACP sheet grades becomes imperative.

Among the vast array of ACP sheet sizes and types available in the market, Aludecor stands out with its standardized and transparently graded offerings. Yet, for customers and professionals alike, questions such as “How many types of ACP sheets are there?” or “What is the standard size of an ACP sheet?” often arise. This blog aims to decode the differences between Aludecor’s most prominent ACP sheet grades AL-33, AL-43, AL-45, and AL-63, shedding light on their composition, ideal applications, and how to choose the right one for your project.

What Do ACP Sheet Grades Represent?

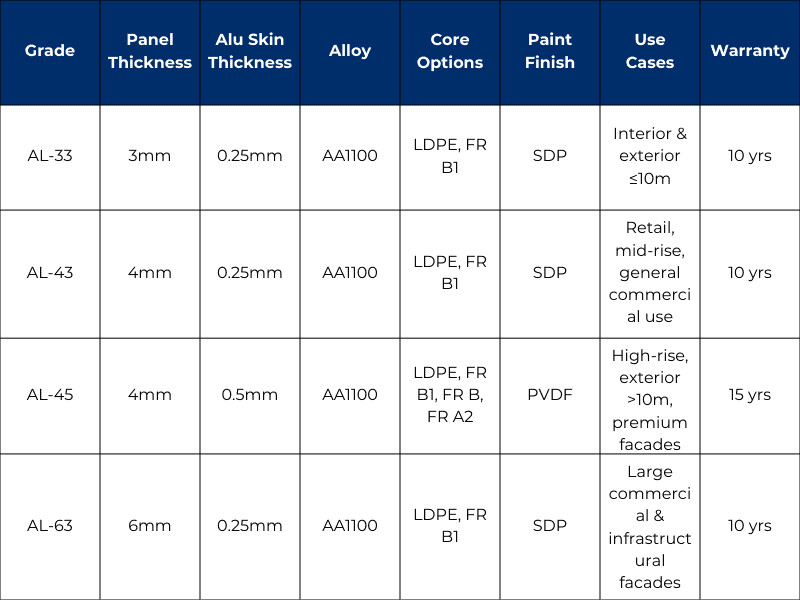

ACP sheet grades are defined by a combination of parameters such as panel thickness, aluminium skin thickness, aluminium alloy type, core material, and paint coating. These factors determine the product’s strength, rigidity, weather resistance, and suitability for interior or exterior use.

For example, the total thickness of ACP sheets can range from 3mm to 6mm. This includes the aluminium skin on both faces, which can vary from 0.12mm to 0.5mm, and a core that may be LDPE (Low-Density Polyethylene), FR B1, FR B, or FR A2 mineral-based variants. The paint type, whether Super Durable Polyester (SDP) or high-performance PVDF, also contributes to the panel’s endurance, aesthetics, and price.

Choosing the correct ACP grade helps balance cost-effectiveness, durability, aesthetic appeal, and compliance with project-specific structural and safety standards.

Why ACP Grades Matter More Than You Think

In high-performance construction and cladding, cutting corners by using the wrong grade can compromise safety, durability, and the visual integrity of a building. Selecting an ACP sheet without verifying its grade can result in underperformance, especially in high-rise or high-exposure projects.

Unfortunately, some manufacturers obscure grade details or use deceptive labelling. Aludecor, however, champions transparency, ethics, and customer empowerment. With each ACP product backed by detailed datasheets, verifiable labelling, and warranty coverage, customers can make confident and informed choices.

Read also: Discover #FutureFacades with Aludecor’s 3D Innovation

How to Verify Aludecor ACP Sheet Grades

- Consult Official Technical Datasheets: Aludecor provides downloadable specifications and catalogues detailing every aspect of its ACP offerings, including grade, thickness, alloy, core, and paint system.

- Check Product Labels & Reverse Markings: Each Aludecor ACP sheet features a visible product code and grade label, including specifications like core type and coating.

- Explore the Aludecor Website: The blog section and product pages offer in-depth insights into ACP sheet sizes, installation tips, and frequently asked questions.

These methods ensure customers can easily differentiate between grades and make project-appropriate selections with peace of mind.

Aludecor ACP Grades Explained

-

AL-33: Reliable, Durable, and Value-Driven

Aludecor’s AL-33 grade is a 3mm ACP sheet that delivers on performance, affordability, and versatility. Designed with a 0.25mm aluminium skin on both sides and manufactured using the AA1100 alloy, AL-33 offers impressive corrosion resistance, which makes it ideal for moderately demanding applications. The panel uses an SDP (Super Durable Polyester) paint coating, delivering a sleek and uniform finish that performs well in both interior environments and exteriors up to 10 meters high.

With core options available in both LDPE and FR B1 variants, AL-33 adapts to diverse project requirements—from retail signage to decorative wall panels. Its lightweight structure ensures easy handling, reducing installation time and costs. Additionally, the panel comes with a reassuring 10-year warranty, cementing its reputation as a dependable solution for general-use applications where aesthetics meet functionality without breaking the budget.

-

AL-43: Versatility Meets Strength

Stepping up in thickness, AL-43 features a total panel thickness of 4mm while maintaining the same 0.25mm aluminium skin as AL-33. This increase in overall thickness translates to improved rigidity and impact resistance, making it a superior choice for projects requiring more robust performance. Like AL-33, AL-43 uses the AA1100 alloy, known for its corrosion-resistant properties, and sports an SDP paint coating for weather protection and long-term color retention.

The 3.5mm mineral or LDPE core provides additional mechanical stability, allowing the panel to perform well in retail, mid-rise commercial buildings, and high-traffic areas. AL-43 is ideal for interior and exterior applications up to 10 meters in height and is backed by a 10-year warranty. Its balanced strength-to-weight ratio and moderate pricing make it a versatile go-to for both aesthetic and structural use cases.

Read also: The Role Of Colour In Façade Design And Its Impact On Branding And Visual Appeal

-

AL-45: Built for High-Rises and Harsh Environments

AL-45 is the premium offering in the 4mm thickness category and is designed specifically for high-rise, high-performance architectural applications. What sets AL-45 apart is its 0.5mm aluminium skin on both sides—double that of AL-33 and AL-43. This substantial increase in aluminium content, along with the use of AA3105 alloy, boosts the panel’s mechanical strength, making it exceptionally resistant to high wind loads, temperature fluctuations, and environmental degradation.

Furthermore, AL-45 is coated with PVDF (Polyvinylidene Fluoride), a paint system known for its high UV resistance and long-lasting colour vibrancy. This makes it an excellent choice for exteriors above 10 meters, where exposure to sunlight, rain, and pollution is intense. AL-45 offers multiple core options, including LDPE, FR B1, FR B, and FRA2, making it highly customizable for buildings that must comply with stringent fire safety norms. The panel also carries a robust 15-year warranty, reflecting its premium stature and reliability in demanding projects such as skyscrapers, airports, and landmark facades.

-

AL-63: Heavy-Duty for the Long Haul

When it comes to maximum panel rigidity and performance, AL-63 stands tall—literally and figuratively. With a total thickness of 6mm, it is Aludecor’s thickest standard ACP offering. The panel includes a 0.25mm aluminium skin on both faces, and a 5.5mm core made of either LDPE or FR B1 material. Manufactured using AA1100 alloy and finished with SDP paint, AL-63 delivers robust weather resistance, thermal stability, and superior mechanical strength.

This grade is tailored for extensive cladding applications in large-format retail spaces, commercial buildings, and public infrastructure projects. Despite its strength, it remains lightweight and easy to install, reducing overall load on building structures. With a 10-year warranty, AL-63 is ideal for projects requiring high panel stiffness and impact resistance across wide surface areas.

ACP Sheet Thickness and Specifications Chart

Conclusion: Match Your Project with the Right ACP Grade

From modest interior renovations to towering architectural marvels, ACP sheets are only as effective as the grade you select. Aludecor simplifies this process by offering a transparent, verifiable grading system, ensuring that you get exactly what your project demands.

Whether you’re an architect designing a cutting-edge skyscraper or a contractor working on a commercial façade, understanding the difference in ACP sheet specifications can save you time, money, and headaches.

Let’s build together

Need expert guidance or assistance with project-specific ACP sheet selection?

📞 Call Aludecor’s toll-free support at 1800-102-0407

🌐 Explore detailed product catalogues and expert advice at www.aludecor.com/enquiry